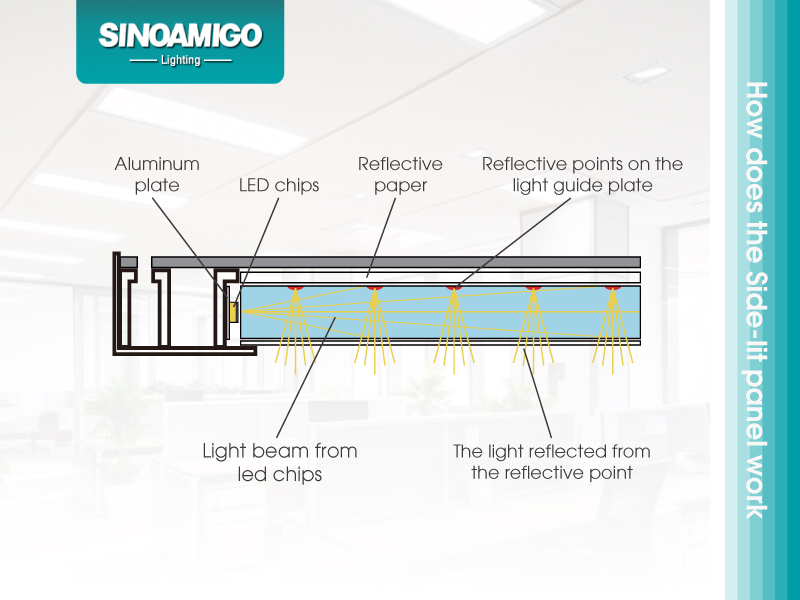

An side-lit LED panel is made of a row of LEDs attached to the frame of the panel, shining horizontally into a light-guide plate (LGP) . The LGP directs the light downwards, through a diffuser into the space below.

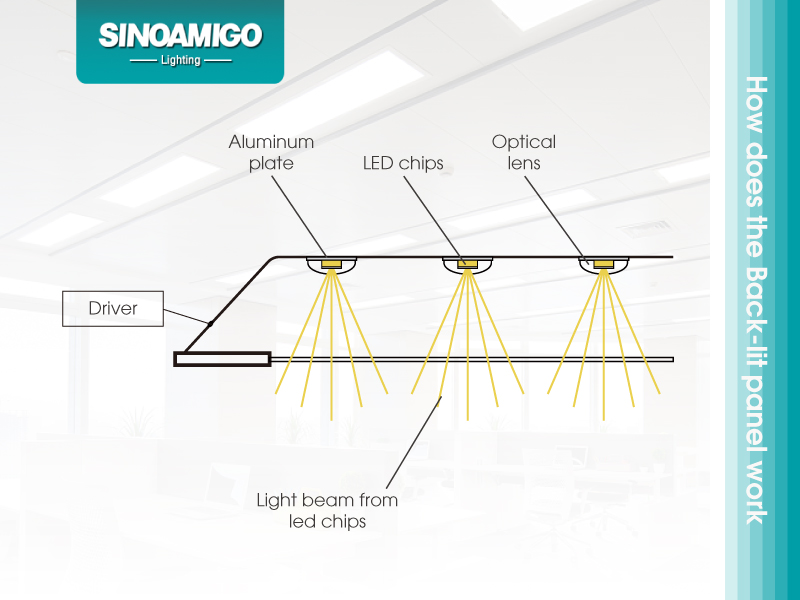

A back-lit LED panel is made of an array of LEDs fitted on a horizontal plate shining vertically down through a diffuser into the space to be illuminated.

Advantages and disadvantages of back lit and side lit panel ligh LED panels

- Side-emitting panel lights have the advantages of being beautiful, simple, luxurious, even and soft in light, ultra-thin in thickness, and easy to install and transport. The light guide plate spreads the light very evenly and avoids the risk of bright spots. The best light guide plate is made of PMMA. Yes, it has a very high light transmittance and will not turn yellow over time; the disadvantage is that it is not easy to achieve high light efficiency, and currently the cost is very high at around 120Lm/W.

- The advantage of direct-emitting panel lights is that the technology and process are relatively simple. The brightness is sufficient and it is easy to achieve high light efficiency. It can currently reach 135lm/w. The lamp will basically not turn yellow. The price has an advantage compared to side lighting. The disadvantage is that the lamp body will be thicker and does not look as high-end as side lighting panel lights. Packing Volume and shipping costs will increase. Because of its hollow structure, it has higher transportation requirements than side-emitting panel lights.

LED side-lit and back lit panel lights each have their own advantages and disadvantages. Their illumination uniformity is good, the light is uniform and soft, and the comfortable lighting effect can effectively relieve eye fatigue. They are used in offices, schools, hospitals, shopping malls, homes and other places, and are widely used lamps. If you are interested in our products when you see this, please contact us.

Post time: Mar-21-2024